Measuring and Inspection

Precision You Can Trust

How we work

At the heart of every successful project is precision and quality assurance. Our measuring and quality control services are designed to ensure that every part and product meets your exact specifications and the highest industry standards.

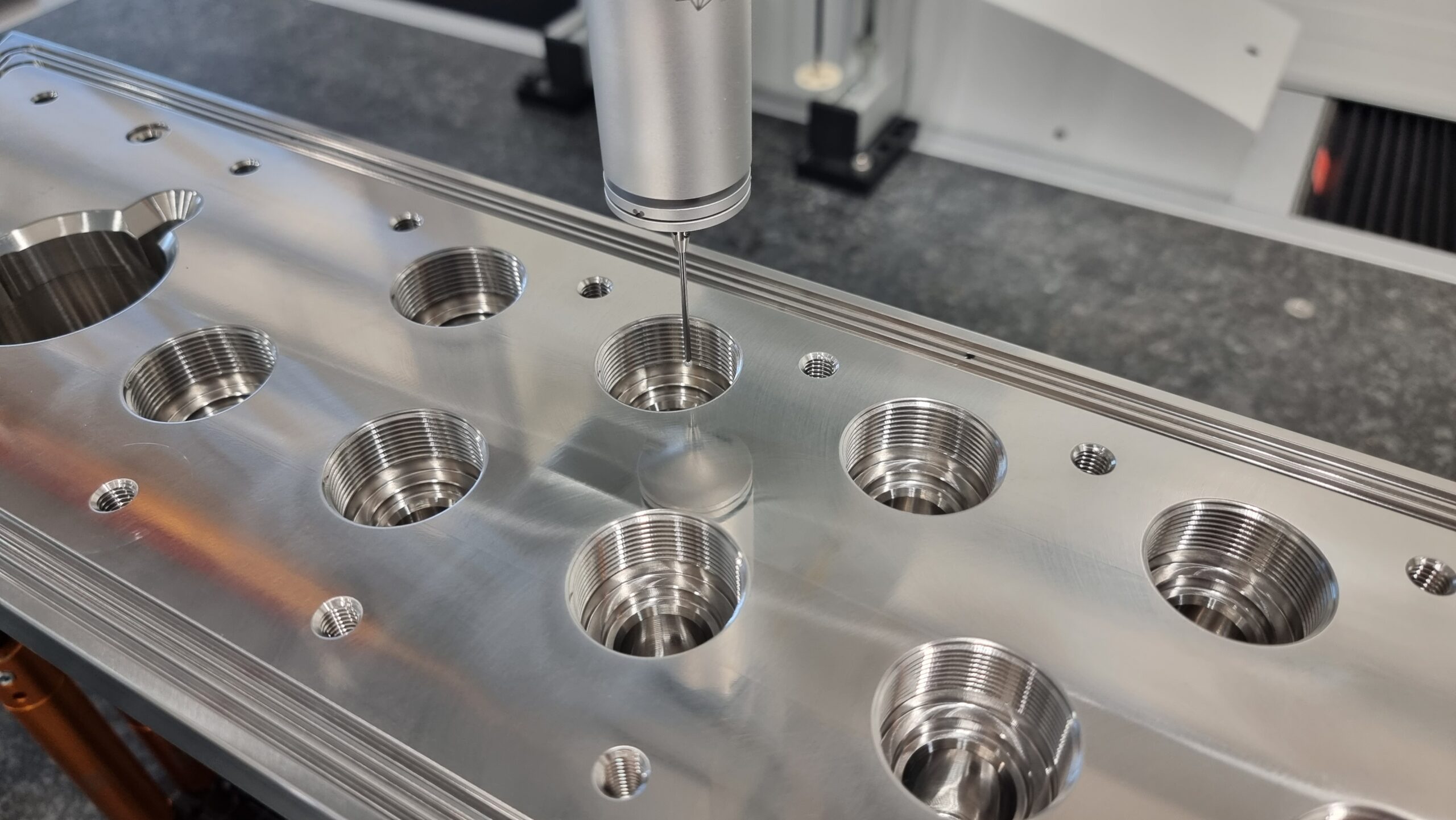

Our measuring lab is environmentally- and vibration controlled, and equipped with CMM-machines, digital- and electron microscopes and boroscope.

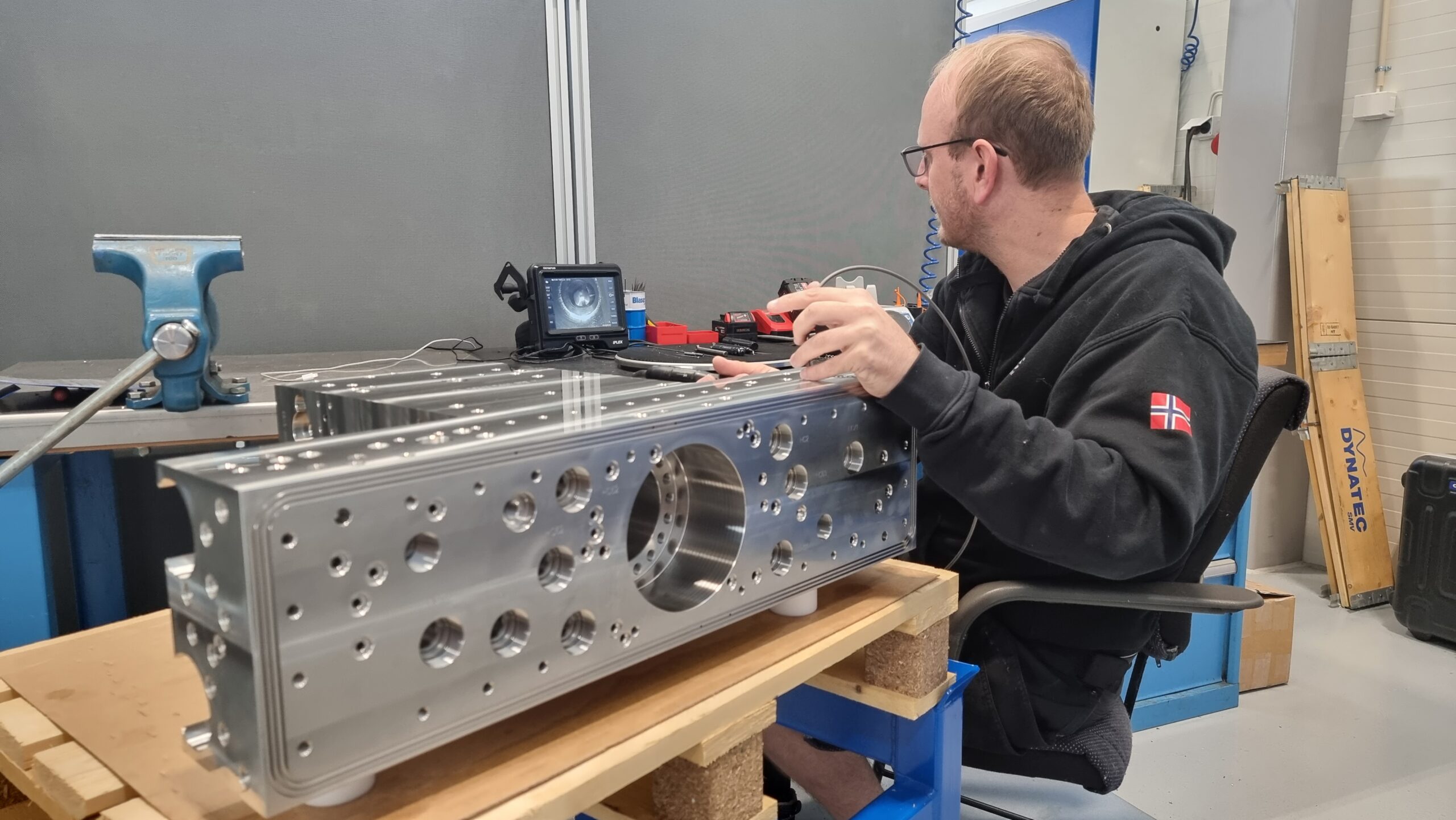

We deliver PMI analysis, boroscope inspections, and dimensional-, surface- and hardness measurement.

We offer documentation and tracebility, and are in compliance with ISO 9001:2015.

State-of-the-Art Equipment

We utilize advanced measuring tools and techniques to deliver precise and reliable results. From dimensional checks to surface finishes, we leave nothing to chance.

Highly Skilled Technicians

Our experienced quality control team ensures that every inspection is thorough and accurate, providing confidence in every project.

End-to-End Quality Assurance

Whether it’s a single prototype or mass production, our quality processes are integrated throughout the production cycle to ensure consistency and reliability.

Advanced Metrology Expertise

At our company, we pride ourselves on delivering precision and reliability in quality control. Our expertise lies in advanced metrology, including Coordinate Measuring Machine (CMM) measurements, which ensure the highest level of accuracy and consistency in every inspection.

Our commitment to precision and innovation ensures that we deliver reliable results, providing peace of mind and confidence in the integrity of your components.

Comprehensive QC Inspection

Lets talk!

Contact us for machining solutions that combine efficiency, precision, and value.