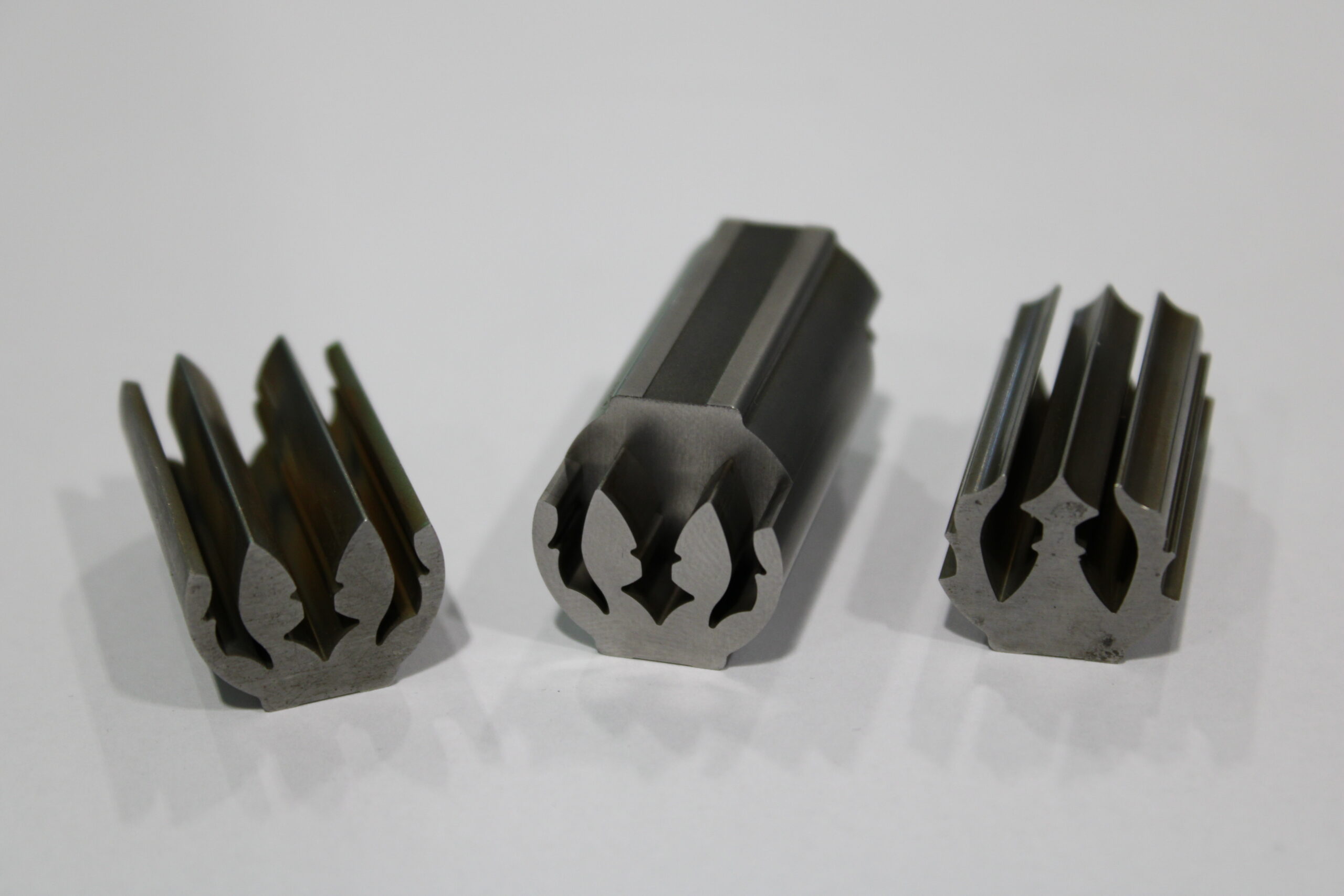

Wire cutting

Reliable, high-accuracy wire cutting

How we work

We can deliver reliable, high-accuracy wire cutting. Perfect for tooling, fine mechanics, and demanding industrial applications, our advanced machine ensures precise cutting of even the most complex geometries.

Advantages of Our EDM Services

-

Extreme Precision

Ideal for complex and detailed components -

Efficient Material Processing

Suitable for hardened steel, titanium, aluminum, and other advanced metals -

Reduced Production Costs

High-quality surface finish minimizes or eliminates the need for post-processing -

High Capacity and Flexibility

Rapid turnaround for both small and large production runs

Technical Specifications Sodik AIC 600G

-

Work Area (X/Y/Z): 600 × 400 × 350 mm

-

Max. Workpiece Dimensions (L × W × H): 900 × 700 × 350 mm

-

Max. Workpiece Weight: 1,500 kg

-

Wire Diameter: 0.15 – 0.3 mm

-

Positioning Accuracy: ± 0.002 mm

-

Surface Finish: Down to Ra 0.3 µm

-

Automatic Threading (ATC): Fast and precise wire rethreading

-

Dielectric Fluid: Water-based system for optimal cutting quality

Ultra-Precision Machining for Complex Geometries

Advanced wire EDM technology allows for the precise machining of complex geometries, achieving accuracy down to the micron level. This process ensures consistent dimensional accuracy and a fine surface finish, making it well-suited for applications requiring tight tolerances and detailed cutting.

Lets talk!

Contact us for machining solutions that combine efficiency, precision, and value.